EagleBurgmann international

EagleBurgmann WORLDWIDE

With around 250 locations and 90 serve centers, we are represented in the most important economic regions of the world. The advantages are clear: short paths to our customers, fast response times and a shared language.

Large seal, low nitrogen requirement

EagleBurgmann has completed tests of the to date largest coaxial, gas-lubricated separation seal "CobaSeal" with positive results. This seal is now also available for shaft diameters of 355 mm and its range of application extends to compressors in any plant in the oil and gas industry such as refineries, LNG and petrochemical plants, for example.

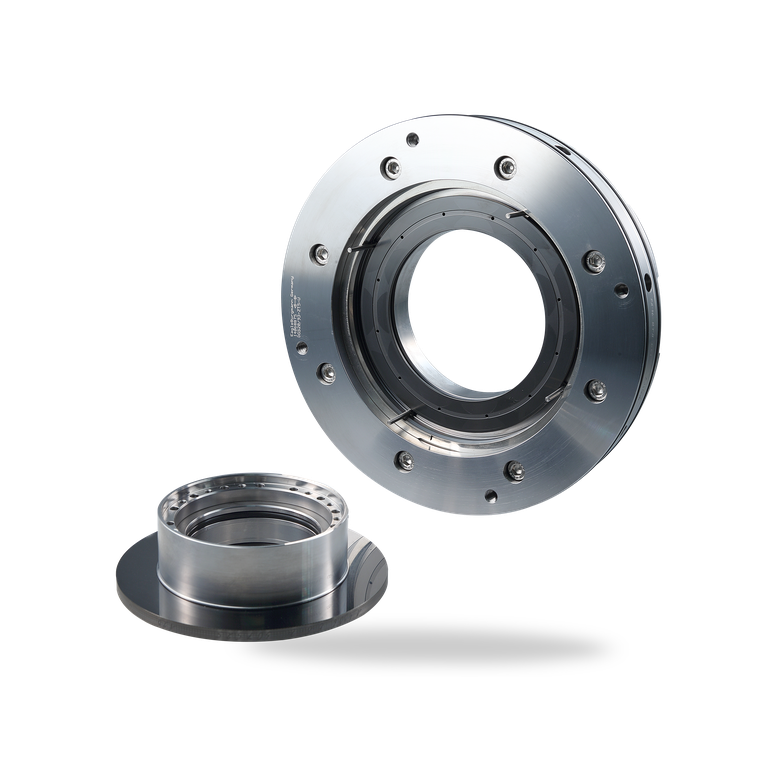

The CobaSeal seals the bearing chamber of the shaft in centrifugal compressors and prevents oil from penetrating the gas-lubricated main seal. It consists of a rotating seat made of ductile material and a stationary, spring-loaded seal face.

Extremely low leakage is an essential feature of the CobaSeal. Compared to separation seals such as labyrinths or seals with carbon rings, the values of the CobaSeal are down by as much as 95 %. The need for nitrogen is reduced accordingly, so much smaller nitrogen generators than usual are sufficient to supply the seal. Compared to conventional sealing solutions on the market, the plant operator can save at least USD 50,000 per year and compressor due to the reduced nitrogen requirement when using one CobaSeal. In addition, the special material combination for the stationary seat and seal face also allows operation with ultra-dry nitrogen.

The design of the seal face and seat ensures that axial and radial movements of the shaft in the sealing gap are easily compensated. The rings are contact-free in any operating condition and thus wear-free as a result. Customer planned maintenance intervals for the plant can be extended accordingly. Even if the main seal fails, the process gas cannot penetrate into the bearing chamber. This considerably increases the operational safety of the compressor.

The CobaSeal works perfectly even under special operating conditions such as extremely low speeds (slow-roll or turning) and when the compressor coasts down. Special settings are not necessary - which is convenient for the system personnel.

Sales via EagleBurgmann Germany in Wolfratshausen and all international branches: Tel. +49 8171 23 0, info@eagleburgmann.com, www.eagleburgmann.com

CobaSeal seal faces for 355 mm and 57 mm shaft diameters

Since its launch, the CobaSeal has proven itself in initial and retrofitting applications worldwide.

The Eagleburgmann Group

Sealing technology for plants and machines

EagleBurgmann is one of the worldwide leading providers of industrial sealing technology. Mechanical seals, seal supply systems, magnetic couplings, carbon floating ring seals, expansion joints, gaskets and packings as well as comprehensive services are used wherever reliability and safety are needed.

Mechanical seals and more

Sealing technology by EagleBurgmann is used worldwide in oil and gas industries, refineries, the petrochemical, chemical, and pharmaceutical industries, food processing, energy, water, mining, paper, aerospace, and other industries. Close to 5,800 employees provide their ideas, solutions, and commitment so that customers can rely on our sealing technology.

What makes us stand out is our excellent quality, great innovative capacity, and an extensive product portfolio for nearly all industrial processes and fields of application. Our product portfolio includes everything from mechanical seals and seal supply systems to magnetic couplings, carbon floating ring seals, expansion joints, and gaskets and packings as well as comprehensive services. Since we are part of the German Freudenberg and Japanese EKK group, we have all the necessary resources for a firmly based reliable partnership.